Developed by British welding laboratory, TWI(The Welding Institute) in 1991, Internationally-patented new technology applied to industries since middle of 90s

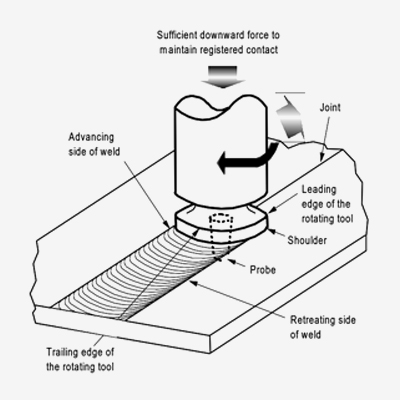

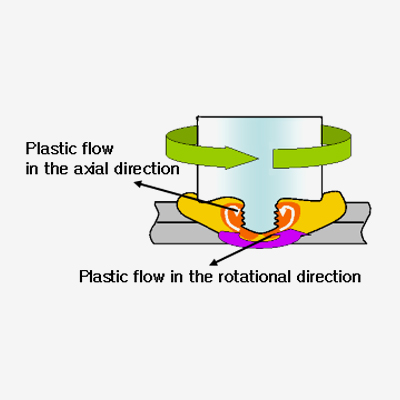

Rotating tool with a profiled probe gives pressure to material. And then friction heat is generated between the tool and the material. The plasticized material by this Heat is stirred by probe and it leaves a solid phase bond between two pieces.

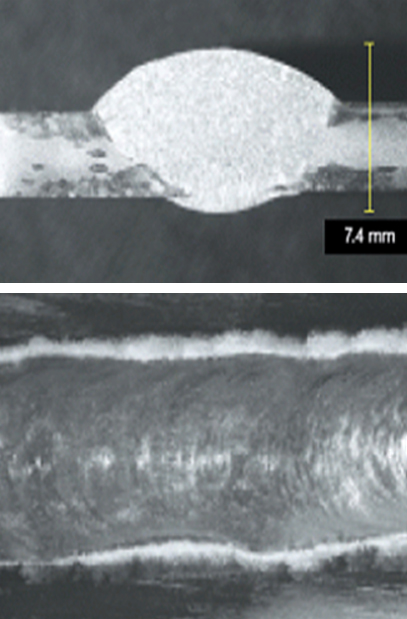

TIG Welding

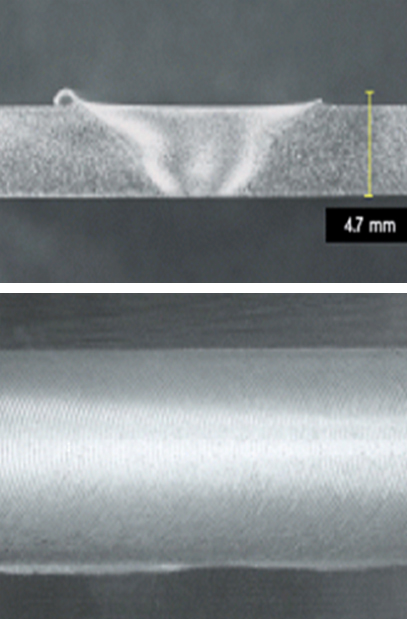

TIG Welding FSW

FSW

MIG : metal-inert-gas arc welding

MIG : metal-inert-gas arc welding| Division | TIG Welding | FSW |

|---|---|---|

| Welding Temperature | Melting point (Tm) or higher | ~0.75*Tm (Non-fusion) |

| Welding deformation | Big thermal deformation | Small deformation (1/10) |

| Mechanical properties | Elongation drop | Good |

| Welding Quality | Occurrence of defects such as craters overlapping, undercut, etc | Good |

| Power consumption | High | Low (2/3 level) |

| Working environment | Occurrence of harmful gases and light | Pollution-free |

| Technician | Skilled technician Necessary | Unskilled person possible |

FSW devices are supplied with excellent design/manufacturing technology for friction stir welding Systems.

-

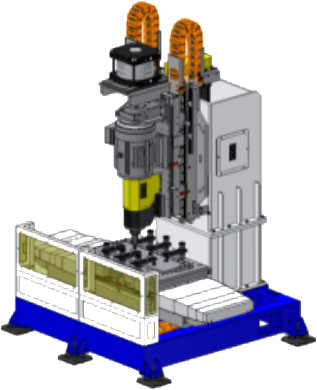

TABLE MOVING TYPE (TW1D-1000Y600Z1T1)

- TABLE : 1000 x 600 x 250

- SPINDLE : max 4,000 RPM

- SPEED X,Y,Z : max 6,000 mm/min

-

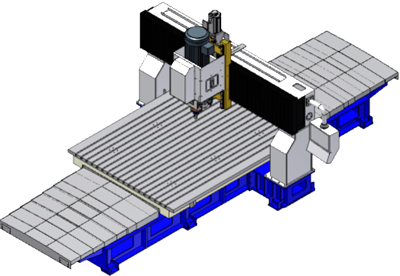

TABLE MOVING TYPE (TW2D-2400Y3000Z3T1)

- TABLE : 2400 x 3000 x 400

- SPINDLE : max 4,000 RPM

- SPEED X,Y,Z : max 6,000 mm/min

-

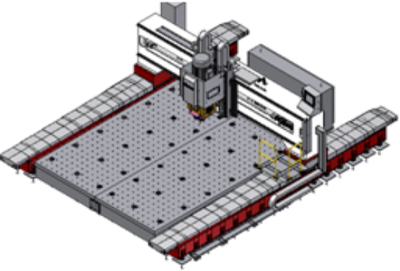

GANTRY TYPE (TW2D-3500Y4500Z2G1)

- TABLE : 3500 x 4500 x 350

- SPINDLE : max 4,000 RPM

- SPEED X,Y,Z : max 6,000 mm/min

-

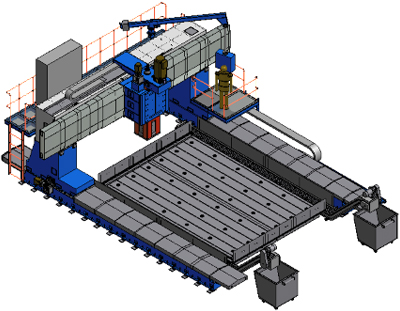

GANTRY TYPE (TW2D-5000Y5000Z3G1)

- TABLE : 5000 x 5000 x 400

- SPINDLE : max 4,000 RPM

- SPEED X,Y,Z : max 6,000 mm/min

FSW Systems Characteristics

-

3-Axis or 4-Axis Stand type

-

Straight and Curved welding is supported.

-

Data collection through software

-

Position & torque-control system using servo system

-

Touch-panel control system

Ordering Information

We supply tools with friction stir welding tool design/manufacturing technology.

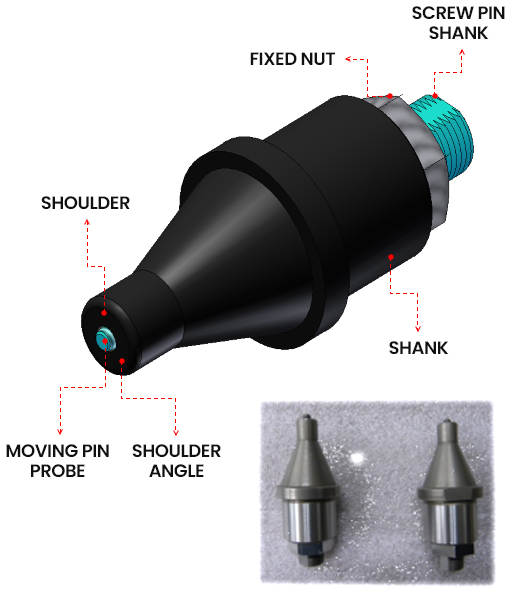

Basic shape & name of each part

3D Tool analysis & precision machining

Feature Optimal Design by 3D Analysis

Securing Productivity

Mobiyc Co.,Ltd

Mobiyc Co.,Ltd